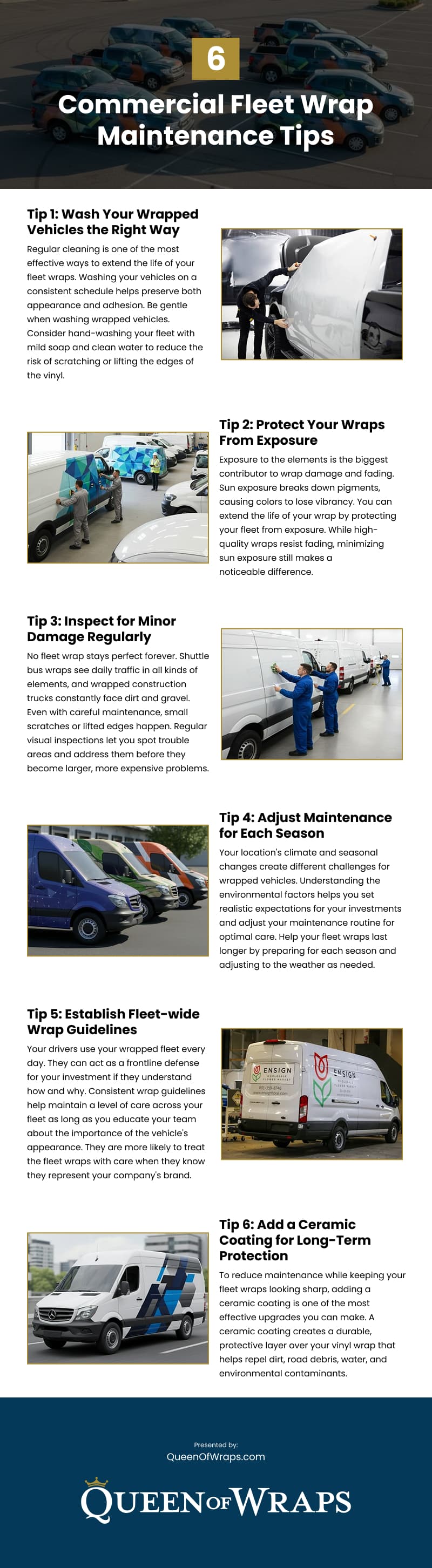

6 Maintenance Tips To Extend the Life of Your Commercial Fleet Wraps

Your vehicles spend long hours on the road and at job sites. Investing in commercial fleet wraps makes that time work for you. But every hour and mile your vehicles cover exposes the wrap to sun, snow, gravel, and debris. The elements wear away at your fleet’s appearance and marketing power.

You can’t control the elements, but you can improve the durability of your wraps by understanding how they wear and how to care for them properly. You can significantly extend their lifespan and keep your fleet looking professional year after year by adding these maintenance tips to your wrap care routine.

Why Long-Term Wrap Care Matters

Fleet wraps represent your brand wherever your vehicles go. A clean, well-maintained wrap signals professionalism and reliability. Faded or damaged wraps send the opposite message, no matter the actual quality of your business.

Maintaining your commercial wraps is part of keeping your brand looking good. Your vehicles can continue to attract attention, and you can continue to maximize your investment by knowing how to protect them.

Tip 1: Wash Your Wrapped Vehicles the Right Way

Regular cleaning is one of the most effective ways to extend the life of your fleet wraps. Dirt, road salt, bugs, and pollutants can slowly degrade the wrap surface if left to sit for extended periods. Washing your vehicles on a consistent schedule helps preserve both appearance and adhesion.

Be gentle when washing wrapped vehicles. Consider hand-washing your fleet with mild soap and clean water to reduce the risk of scratching or lifting the edges of the vinyl. Use soft sponges or microfiber cloths to remove buildup and protect the surface.

You can powerwash your fleet, but you must do so carefully. Hot, concentrated streams of water sprayed directly at the seams of your wrap can lift the edges, allowing water to get under the vinyl and weaken the adhesive.

If you choose to power wash your wrapped vehicles, use cool water on a low-pressure setting with a wide spray angle. Stand 12 to 18 inches from the truck or car, and avoid the edges, seams, and corners of the wrap.

Because most automated car washes use high-pressure jets and stiff brushes, hand washing is preferable. You also can’t control what cleaning products car washes use. Some can damage your wrap. If you must use an automatic car wash, opt for touchless systems only. These are generally safe for wrapped vehicles.

With hand-washing and touchless car washes, avoid harsh chemicals and abrasive solvents. These products can dull the finish and weaken the wrap’s protective layers. Look for vinyl-approved cleaners or use dish soap. Talk to your fleet wrap installer about any special cleaning information if they applied sealants or ceramic coatings for extra durability.

You’ll extend the life of the vinyl and keep your fleet looking polished by gently and regularly cleaning it.

Tip 2: Protect Your Wraps From Exposure

Exposure to the elements is the biggest contributor to wrap damage and fading. Sun exposure breaks down pigments, causing colors to lose vibrancy. Precipitation doesn’t damage the wrap, but it often coincides with corrosive materials, such as road salt or mud, that can cover your vehicle and damage the vinyl. You can extend the life of your wrap by protecting your fleet from exposure.

While high-quality wraps resist fading, minimizing sun exposure still makes a noticeable difference. Park in shaded areas or garages whenever possible to reduce prolonged UV exposure. Consider the temperature of your parking spot as well. Avoid parking in areas where heat reflects off the pavements or buildings during very hot periods.

Consider using UV-resistant wrap materials if you live in an area with many sunny, hot days year-round. Commercial fleet wrap experts in Reno, Nevada, for example, can suggest high-quality vinyl or protective layers to keep your vehicles looking sharp under desert conditions.

You can’t always avoid high surface temperatures or UV rays, especially for large fleets. And it’s challenging to find covered parking when you have dozens of vehicles. In that case, rotate which of your vehicles gets the most direct sunlight. That will help your wraps wear equally across the fleet and maintain your uniform appearance.

In the event of weather conditions such as snow, hail, or heavy rain, promptly rinse off corrosive materials and dry your wrapped vehicle. Water doesn’t harm the wrap unless it’s constantly wet and seeping under the vinyl. In extremely rainy or humid locations, regularly wipe down your fleet and check door and window seals to extend the life of your wrap.

You cannot change the weather. However, these small habits help manage the effects of the elements, preserving both appearance and structural integrity.

Tip 3: Inspect for Minor Damage Regularly

No fleet wrap stays perfect forever. Shuttle bus wraps see daily traffic in all kinds of elements, and wrapped construction trucks constantly face dirt and gravel. Even with careful maintenance, small scratches or lifted edges happen.

Regular visual inspections let you spot trouble areas and address them before they become larger, more expensive problems. Check high-contact spots, such as door edges, handles, mirrors, and lower panels, for early signs of wear. Schedule repairs quickly if you or your team notice peeling edges or surface damage. Small, timely fixes keep moisture and dirt from getting underneath the vinyl.

Preventive maintenance saves money in the long run. Minor repairs are far less disruptive than replacing large sections of wrap that were left unattended for too long.

Tip 4: Adjust Maintenance for Each Season

Your location’s climate and seasonal changes create different challenges for wrapped vehicles. Understanding the environmental factors helps you set realistic expectations for your investments and adjust your maintenance routine for optimal care.

In areas with cold, snowy winters, rinse your undercarriage more frequently and inspect for peeling along the bottom panels. Road salt and ice can degrade materials. Drivers should also avoid scraping ice off their wrapped windows as it may tear the vinyl.

In regions with hot, sunny summers, wash off organic materials such as bugs, bird droppings, and leaves. If this debris bakes on the wrap, removing it can cause tears or leave behind stains. Also, avoid power washes in hot weather. Heat causes vinyl to expand, making it easier for high-pressure jets to lift edges.

Schedule inspections and maintenance during seasonal transitions, such as spring and fall. This can give you a chance to catch wear patterns and plan repairs before the next cycle of extreme weather hits.

Changes in precipitation and temperature will always affect your vehicles, but a well-maintained, high-quality wrap can withstand years of fluctuations. Help your fleet wraps last longer by preparing for each season and adjusting to the weather as needed.

Tip 5: Establish Fleet-wide Wrap Guidelines

Your drivers use your wrapped fleet every day. They can act as a frontline defense for your investment if they understand how and why. Consistent wrap guidelines help maintain a level of care across your fleet as long as you educate your team about the importance of the vehicle’s appearance. They are more likely to treat the fleet wraps with care when they know they represent your company’s brand.

In addition to guidelines about washing, element exposure, and regular inspections, include procedures for regular use. This awareness can improve wrap durability. Your drivers can prevent tears by avoiding tight parking spaces, leaning equipment on their truck, driving through bushes or gravel, and using squeegees on wrapped windows.

You don’t need a complicated system to effectively maintain your fleet wraps. A simple, repeatable routine keeps everything on track without adding unnecessary work for you or your drivers.

A practical care routine usually includes:

- Regularly hand washing with gentle soap

- Visually inspecting wraps during routine vehicle checks

- Promptly reporting minor damage

- Parking under shade in spacious spots when possible

- Driving on well-maintained roads

- Protecting the vehicle’s surface from sharp objects

The key is consistency. These small steps, applied across your fleet, produce noticeable results over time.

Tip 6: Add a Ceramic Coating for Long-Term Protection

To reduce maintenance while keeping your fleet wraps looking sharp, adding a ceramic coating is one of the most effective upgrades you can make. A ceramic coating creates a durable, protective layer over your vinyl wrap that helps repel dirt, road debris, water, and environmental contaminants.

With a ceramic-coated wrap, grime has a harder time sticking to the surface. That means your vehicles stay cleaner longer and require significantly less frequent washing. These innovative coatings save time, labor, and long-term maintenance costs while standing out.

Ceramic coatings also provide added protection against UV exposure. They preserve color vibrancy and slow down fading caused by sun damage. For fleets that spend long hours outdoors or on the road, this extra layer of defense can noticeably extend the life of your wraps.

Depending on the brand and application, ceramic coatings can last up to five years. That long-term wrap protection also helps protect your branding. The finish remains smooth, glossy, and professional while making routine cleaning faster and easier.

If you’re looking for a way to protect your investment, reduce upkeep, and keep your fleet looking amazing with less effort, ceramic coating is a smart addition to your wrap care strategy.

A Little Work for a Lot of Value

By understanding what affects wrap lifespan and how to address and care for them, you extend the life of your wraps and preserve their impact. Fleet wraps work hard for your business. With a little consistent care, they continue to deliver value for years to come.

Infographic

Fleet wraps showcase your brand everywhere your vehicles go, and a clean, well‑maintained wrap signals professionalism and reliability. Keeping your commercial wraps in top condition is essential for protecting your brand image. This infographic shares practical maintenance tips for commercial fleet wraps.